Forgeline Motorsports

F01

F01

Couldn't load pickup availability

Forgeline Flow Formed Series wheels are 100% designed and engineered by Forgeline, in our Dayton, Ohio headquarters, and manufactured by our performance and quality proven partner. Over the last five years, we’ve developed our newest series of wheels utilizing advanced flow forming techniques and processes reserved for only the highest quality wheels in this category. We start with a tuned Tilted Gravity Cast (TGC) method; yielding an initial casting that is both stronger and lighter than common methods used by many other flow formed wheels. The barrel is then formed using the newest Cold Vertical Flow Form Technology. This maintains a steadier spin angle and consistent material temperature to deliver a higher quality result and better overall material structure compared to common hot, horizontal processes.

The resulting Flow Formed F01 wheels not only look great but are appropriately lightweight and have a street tire load rating of 1500 pounds per wheel. With decades of engineering race wheels, we’ve taken this expertise and dedicated years to developing the best out-of-the-box, high-quality performance street wheel that is both budget and time friendly. 100% Forgeline designed and 100% Forgeline engineered!

View the Complete Application Guide Here

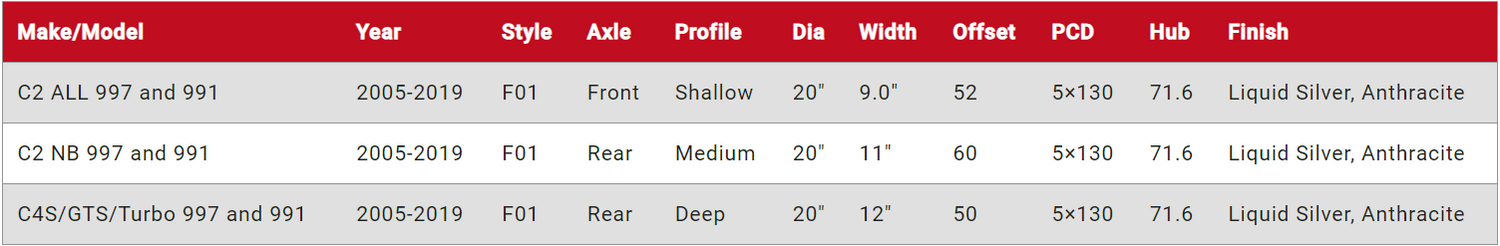

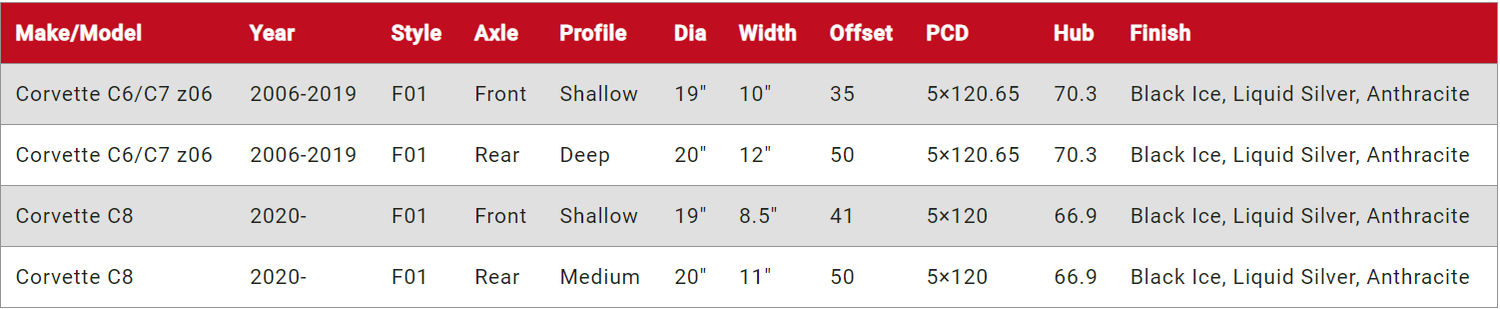

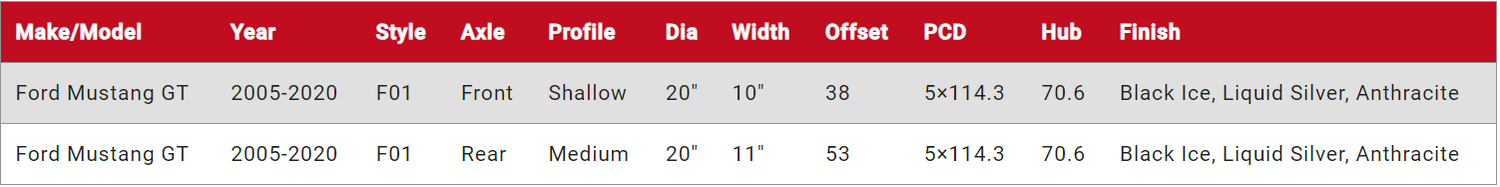

Available sizes and fitments are listed in application guide above.

*Price is per wheel, please select minimum qty of 2

Share

-

Step 1

The Flow Formed process is started by placing a pre-heated Casted Wheel on a specially designed inner barrel mold.

-

Step 2

Rollers press into the wheel as it spins on the mold, flowing the aluminum thinner, forming the shape of the inner rim; all while increasing the tensile strength.

-

Step 3

The inner rim profile is finalized to meet tire mounting specifications. The final product is stronger, lighter, with increased metal yield and compressive strength.

Camaro

Corvette

Mustang

Porsche